Eenvoudig leven

Een eenvoudig leven betekent niet dat je ongemak uit de weg gaat. Je kiest bewust welk ongemak je aandacht geeft. Je maakt bewuste keuzes wat je wel en wat je niet (meer) doet.

Begin nu met jouw innerlijke ontwikkeling naar een eenvoudig leven.

Of, plan eerst een kennismaking.

Wat is je uitdaging?

Je to-do lijsten worden maar niet korter en je werkt te veel mee in de operatie.

Wat wil je?

Je wil ruimte maken voor de strategische ideeën die al lang op jouw wensenlijst staan. Je wil dat de mensen in je team met oplossingen komen, dat ze verantwoordelijkheid voelen en zelf besluiten nemen.

Waarom?

Je hebt een missie. Jullie bedrijf moet toekomstbestendig blijven en je wil een eenvoudig leven.

Zo verander je de resultaten

We werken een kwartaal aan jouw innerlijke ontwikkeling met vaste gewoontes. We werken samen aan je relatie tot zelf, denken, verbinden, samenwerken en handelen, met korte dagelijkse acties. Een compact programma om bewust te werken aan de innerlijke ontwikkeling voor een eenvoudig leven.

Daarnaast is Erno de accountabilitypartner en mentor voor vrouwelijke ondernemers. Hij luistert, stelt kritisch vragen en geeft advies op jouw verzoek, plan direct een kennismaking.

Erno houdt je bij de les, loodst je door de prioriteiten en helpt je om stap voor stap de juiste besluiten te nemen, zodat jullie impact groeit en bloeit.

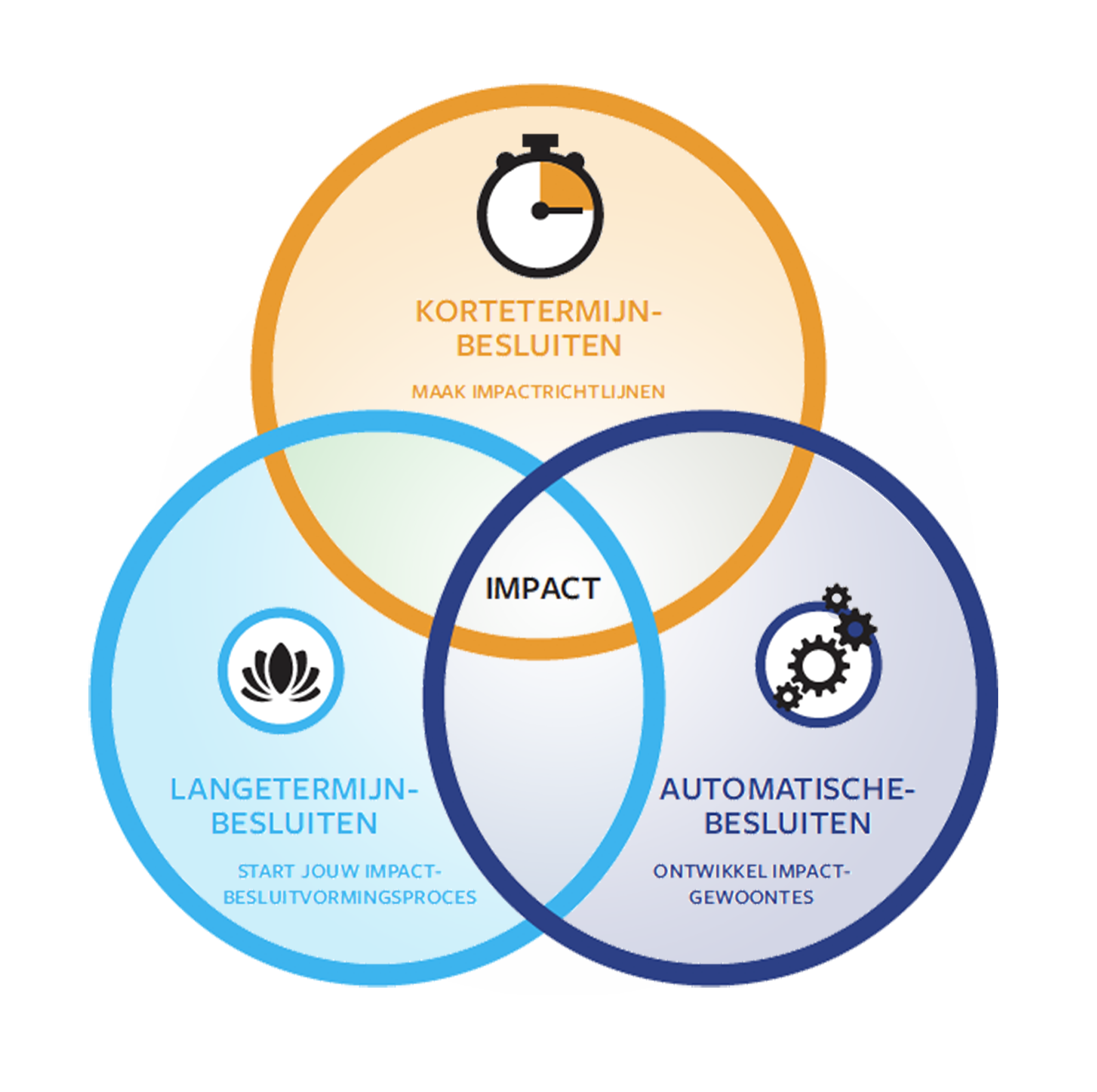

Als je deze whitepaper gelezen hebt, dan heb je de kennis en de hulpmiddelen om besluiten te nemen met aandacht, dan kun je uit de waan van de dag komen, het belangrijkste werk oppakken en afronden.

Deze whitepaper heb ik geschreven om ondernemers zoals jij te helpen om hun besluitvormingsproces te veranderen zodat je bedrijf groeit in impact.

Een gesprek met Erno leidt altijd tot nieuwe inzichten

Erno is een businesscoach die je helpt met besluiten nemen, maar je ook een breder perspectief laat zien. Een gesprek met Erno leidt altijd tot scherpe, nieuwe inzichten.

Johanna Oosterbaan, ondernemer bij Gouden Website

Contact opnemen?

Zie waarom je dit wilt, lees eerst de veel gestelde vragen.

Erno in 10 seconden

Erno is de accountabilitypartner voor ondernemers die impact hebben en willen uitbouwen. Onderzoekt besluitvorming. Deelt zijn inzichten hierover in, artikelen, boeken, podcast, nieuwsbrieven en hulpmiddelen. Heeft terugdringen van sociale en ecologische ongelijkheid als levensmissie.

Vader van twee kinderen, man van M., loopt hard, scheidsrechter voor de KNVB en gebruikt stoïscime voor rust.

Erno in 10 minuten en wat doet hij nu?

Zie zijn “over” pagina en dit doet hij “now” pagina.

Podcast

Luister direct naar de Decide for Impact podcast over besluitvorming en impact in de praktijk met ondernemers die het doen en De Ondernemers Boekencast waarin hij samen met Tom boeken voor ondernemers bespreekt.

Abonneer via Apple, Spotify, Overcast, Stitcher, Google, Player.fm, Podbean of kopieer de RSS feed in jouw favoriete podcast speler.

Recente Impact Boeken

Krachtig format: je leest het in een keer uit en het zet je goed aan het denken. Ik ga het delen met een bevriende ondernemer!

Dr. Willem Schramade

The Sustainable Finance Factory

Impactbesluiten waarmee je nieuwe medewerkers aantrekt

Voor leiders die nieuwe medewerkers willen aantrekken om de impact van jullie bedrijf op te schalen. Het nieuwste boek dat de Inner Development Goals (IDG’s) toepast.

Impactbeslissingen voor een leider

Speciaal voor leiders die werken aan het opschalen van de impact van het bedrijf. (gratis zo lang de voorraad strekt)

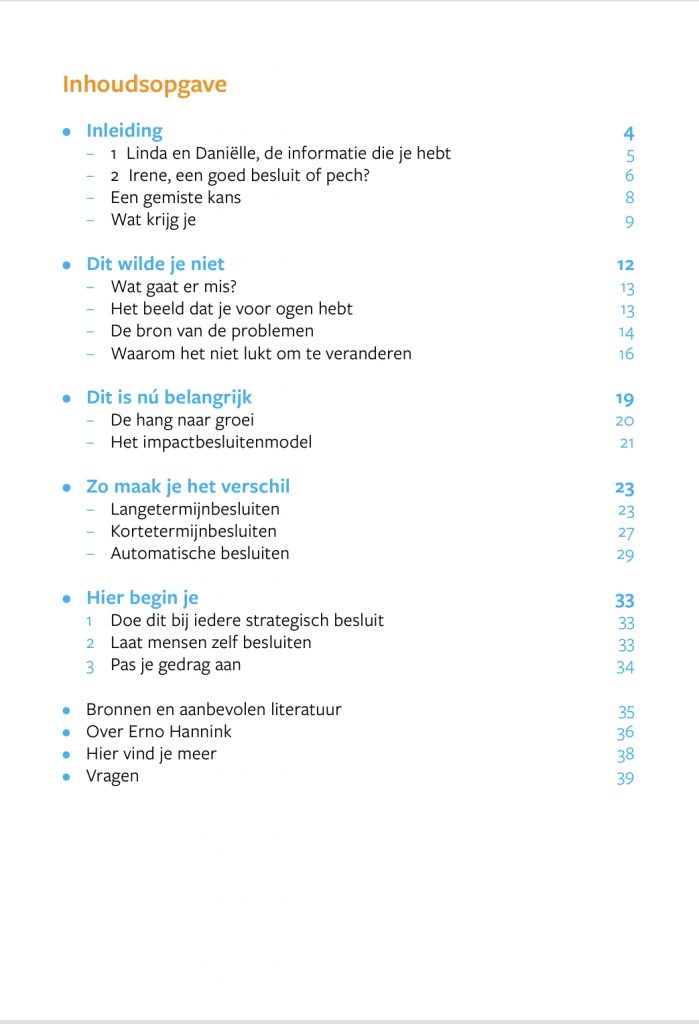

Impactbeslissingen voor welvaart en welzijn

Voor ondernemers die werken aan de groei van de impact van het bedrijf waarmee je welvaart en welzijn voor alle betrokkenen realiseert.

“Erno: een man met impact”

Ik ervaar ieder coachgesprek met Erno als een onmisbaar element in het groeiproces van onze onderneming.

In deze fase van ons bedrijf hol ik mijzelf als ondernemer snel voorbij. Slecht voor mijzelf en voor mijn club.

Erno brengt mij met scherpe vragen en ervaren opmerkingen weer terug bij mijn hoofddoel.

Docwolves toonaangevend in besluitvorming.

Rens Groeneveld

CEO DocWolves

Gezien in

Waardevolle artikelen voor jou

- Mijn drie woorden voor 2024 #my3words

- Minder doen, maar beter

- In verbinding met anderen

- Formuleer jouw visie van de toekomst

- Vind focus en energie met je innerlijke kompas

Alle artikelen

Waardevolle podcast afleveringen voor jou

- De crisis van het democratisch kapitalisme #boekencast afl 97

- Grond en vermogen laten doorstromen voor de economie – Damaris Matthijsen

- An invitation to contribute – Isabelle Swiderski

- Limitarisme #boekencast afl 96

- Dealing with complexity and shaping sustainable transformation – Barbara Holzner

Alle afleveringen

Wat Klanten Vertellen

Ik ben jong, en heb vanzelfsprekend belemmerende overtuigingen die ervoor zorgen dat je niet de stappen kan zetten die ik wil zetten. Met name in de fase waarin we als bedrijf zitten, is het goed om een spiegel te hebben voor je eigen gedachtes.

Er zijn verschillende concrete verbeteringen aan ons bedrijf bedacht en inmiddels geimplementeerd. Door deze aanpassingen is intern beter duidelijk wie verantwoordelijk is voor welk proces, is er een MT ingericht en zijn er stappen gezet om richting een nog plattere organisatie toe te werken, duurzame initiatieven gestart (zoals het opzetten van overwinst), we zijn kansarme jongeren gaan helpen in Uganda door middel van traineeships en vanaf 2024 starten we met ‘vrijwilligersdagen’ vanuit DoubleSmart.

Erno heeft enorm veel kennis over hoe de wereld werkt en heeft daar een hele duidelijke visie over. Een visie die ik vanuit mijn omgeving niet vaak meekrijg. Ik denk dat je altijd op zoek moet naar hoe de wereld werkt en hoe je zelf werkt, en daar heeft Erno me super goed mee geholpen.

Rick Zuidbroek

- Fijn om met iemand te kunnen sparren die kritisch is op taal- / woordgebruik / denkpatronen

- Andere inzichten, als ondernemer ben je vaak omringt met collega ondernemers die vrij rechtse standpunten hebben, die ik ook zeker heb, maar ik heb op dat vlak heel veel geleerd over en een completer beeld gekregen van hoe de wereld in elkaar steekt

- Er zijn concrete resultaten uitgekomen die het bedrijf hebben geholpen om vorig jaar weer 40% te groeien.

Eigenaar DoubleSmart en DoubleWeb

“Gun het jezelf en je bedrijf om groter dan huidige zelf te groeien.”

Het is lastig om extern hulp te vragen, hoe goed je ook beseft dat dat goed is voor jezelf en je business. Je wil dus een bepaalde ‘zekerheid’ weet die persoon dan meer dan jij? Maar daar gaat het niet om, het is het andere perspectief wat je jezelf sowieso niet kan bieden. Ongeacht of die coach nu wel ‘goed genoeg’ is. Business coaching met Erno geeft inzichten en aandachtspunten die jezelf niet ziet. Het helpt je te focussen op dingen zodat je echt kan groeien.

De persoonlijke aandacht vond ik het leukste. Erno luistert naar wat je wil, waar je staat en denkt mee naar hoe je daar komt. Versterkt door kleine persoonlijke attenties.

Daarnaast helpt de business coaching in mijn reflectie. Je wordt verplicht stil te staan bij dingen waar je anders geen tijd voor neemt. En die tijd is wel belangrijk (werken in je bedrijf vs aan je bedrijf) En in mijn zelf ontplooiing. Onbewust saboteer je jezelf bij groei. Zijn business coaching is een stok achter de deur om dingen toch te doen.Verder het sparren, wat werkte bij anderen wel of niet. Om betere beslissingen te kunnen nemen.

Erno´s business coaching zou ik zeker aanbevelen aan anderen. Gun het jezelf en je bedrijf om groter dan huidige zelf te groeien.

Esther Gons

managing partner NEXT Amsterdam

“hoe belangrijk het is om focus in mijn werk te brengen”

Erno leerde me hoe belangrijk het is om focus in mijn werk te brengen. Daarnaast heeft hij ervoor gezorgd dat ik mijn belangen scherper in de gaten houd. Dat liet hij me krachtig en liefdevol zien in het wekelijkse contact dat we hadden.

Connie Maathuis

Ondernemer, bestuurder en toezichthouder

“De omzet is door de businesscoaching sneller gestegen”

Op dit moment levert het elke keer weer nieuwe inzichten op waarmee wij onze dienstverlening kunnen optimaliseren en betere keuzes kunnen maken voor Two-Inspire.

Ik vind het supergoed dat je ons elke keer weer spiegelt en weer met nieuwe inzichten de deur uit laat gaan.

Het voelt vertrouwd om maandelijks een moment van reflectie te hebben.

De omzet is door de businesscoaching sneller gestegen.

We hebben meer structuur gekregen in onze bedrijfsvoering.

Het feit dat je ons stimuleert echt specialist in 1 ding te worden vind ik wel heel krachtig. We merken dat dit ook door de klanten opgemerkt wordt en dat we vaker terug gevraagd worden.

Martijn de Haan

Ondernemer, Two-Inspire

“Voor elke ondernemer bijna een noodzaak zou ik willen zeggen”

Het idee dat je eigenlijk geen tijd hebt om een coach te spreken. Daarnaast dat je nog niet precies weet wat het je kan brengen. De meerwaarde zie je pas als je de vruchten ervan gaat plukken.

Het resultaat voor mij is meer focus op de juiste dingen. Inzicht in hoe je je eigen beslissingen neemt en waar daarin de valkuilen liggen. Even uit je waan van de dag stappen en samen met de coach kijken naar het grotere plaatje.

De ontspannen sfeer waarin de gesprekken plaatsvinden. En dit zorgt er ook juist voor dat je overzicht krijgt en rustig vanaf een afstandje naar je bedrijf kunt kijken.

De mogelijkheid om te klankborden en je eigen ideeën te toetsen.

Het delen van kennis van de coach vanuit zijn eigen ervaringen en die toepasbaar is op onze eigen organisatie.

De confrontatie met jezelf; soms ben je echt overtuigd van een idee of richting en houdt de coach je een spiegeltje voor die je een heel andere kant opstuurt.

Zeker zou ik de business coaching aanbevelen aan anderen. Zonder feedback loop je alleen je eigen ideeën achterna, heb je oogkleppen op en vergeet je dat je samen veel verder komt.

Jezelf laten coachen is niet zomaar een makkelijke beslissing. Het is een actieve stap die je zet in een richting waarvan niet helemaal duidelijk is wat het je gaat brengen. Dit vergt dus enige moed en visie. Maar als je het doet en je stelt je er echt voor open, dan levert het je altijd winst op, soms op terreinen waarop je het helemaal niet had verwacht. Voor elke ondernemer bijna een noodzaak zou ik willen zeggen.

Jaap Sikkema

Ondernemer, Proximo en De Schout Gerechtsdeurwaarders

Laten we verbinden

Hi, ik ben Erno Hannink. Als accountabilitypartner en mentor heb ik ondernemers en hun teams geholpen met inzichten en besluiten nemen waardoor ze groeien in duurzame positieve impact op mens en omgeving. In de afgelopen 17 jaar heb ik meer dan 1250 klanten geholpen bij meer resultaat voor hun bedrijf. Tijd om te praten over jouw keuzes voor de toekomstbestendigheid van jullie bedrijf?

Dit is geheel vrijblijvend.